Trusted Arise From the Materials Test Lab

Wiki Article

Cutting-Edge Material Screening Research Laboratory: Accelerating Advancement With Precision

Are you looking for a sophisticated product testing research laboratory that can accelerate your innovation with accuracy? Look no more. Our cutting edge center is furnished with advanced screening devices and utilizes cutting-edge testing approaches. With our precision dimensions and analysis, we can help you increase your materials research study. Experience the power of advanced modern technology in material screening and take your development to brand-new heights.Advanced Testing Devices

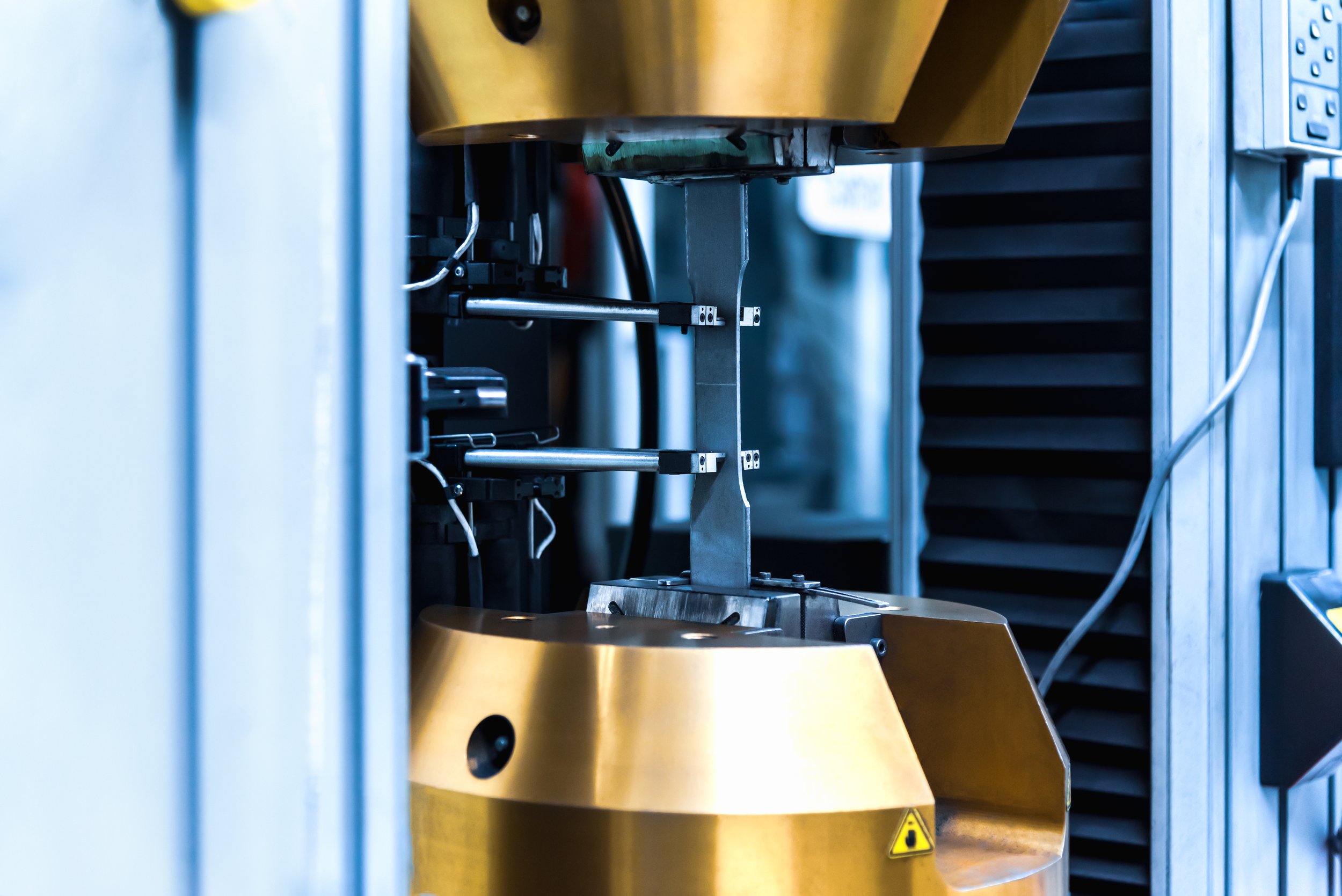

You need to take a look at our innovative testing devices, it's state-of-the-art and will aid you accelerate development. Our sophisticated laboratory is furnished with the latest technology to ensure precise and specific screening of products. With our advanced devices, you can anticipate reliable results that will drive your advancement onward.One of the essential tools in our lab is the modern global testing device. This maker can executing a wide variety of tests, such as flexural, compression, and tensile tests. With its high capacity and advanced control system, you can confidently evaluate the stamina and sturdiness of your products.

Along with the global screening maker, we additionally have actually progressed spectroscopy devices. This devices enables you to evaluate the chemical structure of your materials with terrific accuracy. By understanding the composition of your materials, you can make informed choices concerning their efficiency and suitability for your particular applications.

Additionally, our laboratory is equipped with cutting-edge microscopy tools. This permits you to take a look at the microstructure of your materials in detail. By studying the microstructure, you can obtain understandings into the material's properties and possible locations for improvement.

Innovative Examining Techniques

One of the techniques we use is non-destructive testing, which allows us to assess the stability of products without causing any type of damages. By utilizing sophisticated imaging modern technologies such as ultrasonic testing and X-ray assessment, we can analyze the inner framework of materials and determine any kind of issues or flaws. This method not just conserves time and resources but likewise makes certain that the material remains intact for additional screening or usage.

Our laboratory is devoted to pressing the limits of material testing by employing these cutting-edge approaches. With better precision and effectiveness, we can offer our clients with reliable information and understandings that drive advancement and enhance product growth procedures. Trust fund us to provide accurate and reputable product screening results that will propel your tasks to brand-new heights.

Precision Dimensions and Analysis

Among the methods we're utilizing is non-destructive testing, which enables us to assess products without causing any type of damages. With precision dimensions and analysis, we can explore the structure and properties of different products, enabling us to enhance their performance and improve technology. By employing innovative technologies, such as X-ray imaging, ultrasonic testing, and infrared thermography, we can get accurate and in-depth info about the interior framework and honesty of materials without changing their physical or chemical properties.With non-destructive screening, we can recognize any problems, problems, or problems that might exist within visit homepage a material, ensuring its dependability and safety and security. This approach allows us to spot concealed splits, gaps, or weak points in a non-invasive manner, saving time and resources while alleviating prospective threats. By determining these concerns early on, we can proactively address them, stopping pricey failings or crashes in the future.

In enhancement to detecting flaws, precision measurements and analysis also enable us to evaluate the efficiency and top quality of products. We can gauge vital features such as solidity, deterioration, flexibility, and stamina resistance, offering valuable understandings for product choice and design optimization. By understanding these properties, we can create brand-new materials with enhanced capability and toughness, pressing the boundaries of technology.

Accelerating Products Research Study

By employing non-destructive screening techniques, we're able to promptly assess and analyze numerous materials, enhancing the rate and efficiency of our products research study. These non-destructive testing techniques allow us this page to check out the residential properties of materials without creating any type of damages, saving time and sources in the process. With strategies such as ultrasonic testing, radiography, and magnetic fragment assessment, we can determine the interior structure, problems, and defects of products accurately and quickly.The benefit of non-destructive testing is that it permits us to gather useful data while protecting the honesty of the materials being examined. We can assess the high quality, integrity, and performance of various products without compromising their performance. This is specifically essential when functioning with unusual or pricey samples, as harmful screening would result in their damage and possible waste.

Along with saving time and sources, non-destructive screening additionally improves the security of our study tasks. By avoiding the need to physically change or damage down materials, we reduce the danger of crashes or problems during testing. This guarantees a safe and regulated atmosphere for our specialists and researchers.

Cutting-Edge Modern Technology in Product Testing

Using state-of-the-art modern technology, we can promptly and properly examine the homes of different materials. With our sophisticated devices and methods, you can save time and sources in the product testing procedure - materials test lab. Our sophisticated devices permit specific dimensions and analysis, offering you an extensive understanding of the product's strength, sturdiness, and other vital attributesThink of having the ability to figure out the precise make-up of a material within minutes, instead of waiting days or even weeks for typical testing approaches. Our innovation enables you to do just that. By utilizing non-destructive screening methods, we can take a look at the internal framework of materials without creating any damages, ensuring that the honesty of the samples is protected.

Furthermore, our devices provides real-time data, permitting you to make informed choices quickly. You can examine the efficiency of different products and recognize any type of weak points or areas for enhancement. This rate and precision not only enhance the screening process however additionally drive development by allowing you to repeat and refine materials a lot more efficiently.

Conclusion

You have actually simply explored the world of an innovative product testing laboratory, where advancement is increased with precision. By utilizing sophisticated screening tools and innovative methods, this lab is at the leading edge of products study. With its precision measurements and analysis, it enables a deeper understanding of product buildings. By embracing cutting-edge technology, this lab remains to push the limits of what is possible in material testing. Whether you're a scientist, designer, or merely interested concerning the globe of products, this lab is a hub of interesting discoveries.One of the methods we're making use of look at here is non-destructive screening, which enables us to evaluate materials without creating any type of damage.By employing non-destructive screening techniques, we're able to quickly review and assess different materials, boosting the speed and efficiency of our products research study. These non-destructive testing approaches enable us to examine the properties of products without causing any kind of damage, saving time and sources in the process.You have actually just discovered the world of a sophisticated material screening lab, where innovation is increased with precision. By making use of advanced screening equipment and cutting-edge methods, this research laboratory is at the forefront of products research.

Report this wiki page